Description

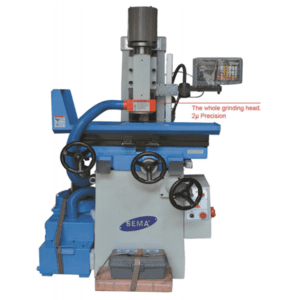

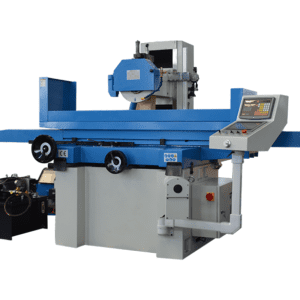

Grinding Machine Description

Usage

- Inch Start: Used for incremental movements to start operations precisely.

- Crude Feed & Fine Feed: Adjust the amount of material being fed into the grinding process.

- Z Axis: Controls vertical movement, crucial for precise grinding depth adjustments.

- Stepper Motor Driver: Manages the stepper motor, providing precise control over movement.

- Computer Automatic Feed: Automates the feed process, improving efficiency and consistency.

- Fast Rise to the Origin: Quickly moves the machine to the initial position for setup or resetting.

- Work Surfaces: Refers to the area where the workpiece is placed and ground.

- Full Auto: Indicates the machine operates with full automation capabilities.

- Vertical AC Servo Motor: Provides precise control over vertical movements.

- Cross & Longitudinal Motors: Control the machine’s cross and longitudinal movements respectively.

- Hydraulic Controller: Manages hydraulic components for various machine functions.

- PLC Servo: Programmable Logic Controller (PLC) used to control servo motors and other automation functions.

- GS-PLC: Specific model of PLC used in the system.

- Touch: Refers to the touch screen interface for controlling and programming the machine.

| Term | Description |

|---|---|

| 2ND Fast, Slow Down | (Rapid descent, slow descent) |

| Inch Start | (Incremental start) |

| Crude Feed | (Rough feed) |

| Fine Feed | (Precise feed) |

| Z Axis | (Vertical axis) |

| Empty Grinding | (Empty grinding) |

| Computer Automatic Feed | (Computer-controlled automatic feed) |

| Stepper Motor Driver | (Driver for stepper motor) |

| Fast Rise to the Origin | (Rapid rise to origin) |

| Work Surfaces | (Work surfaces) |

| Full Auto | (Fully automatic) |

| Vertical AC Servo Motor | (Vertical AC servo motor) |

| Cross Motor | (Cross motor) |

| Longitudinal Motor | (Longitudinal motor) |

| Hydraulic Controller | (Hydraulic controller) |

| PLC Servo | (PLC servo) |

| GS-PLC | GS-PLC (Specific PLC model) |

| Touch | (Touch) |