Description

Overview

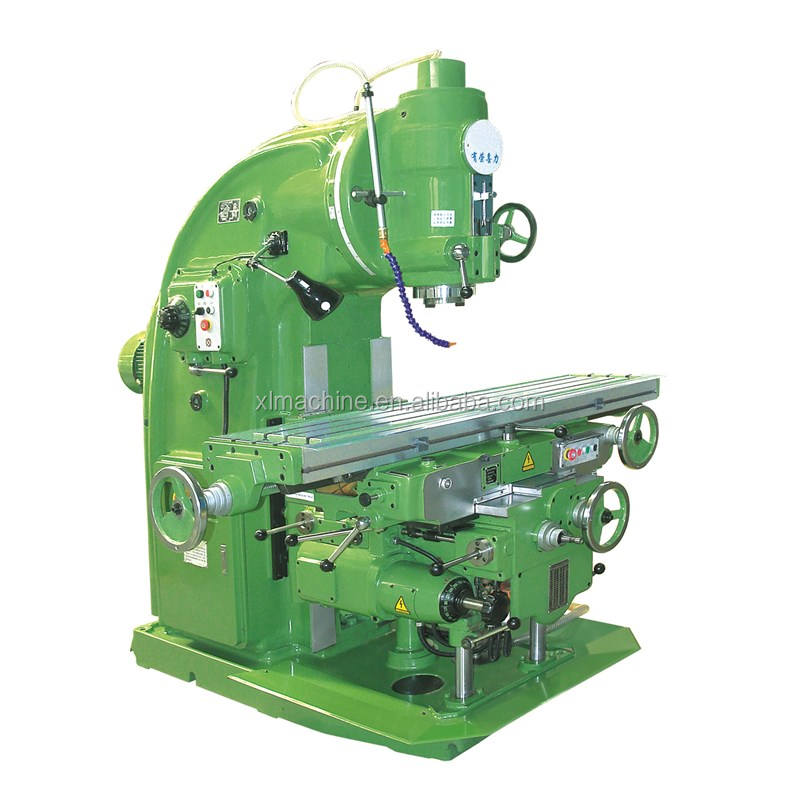

XL8145 CE certificate tool milling machine UM300A UM400A vertical and horizontal universal metal miller

Brief Introduction

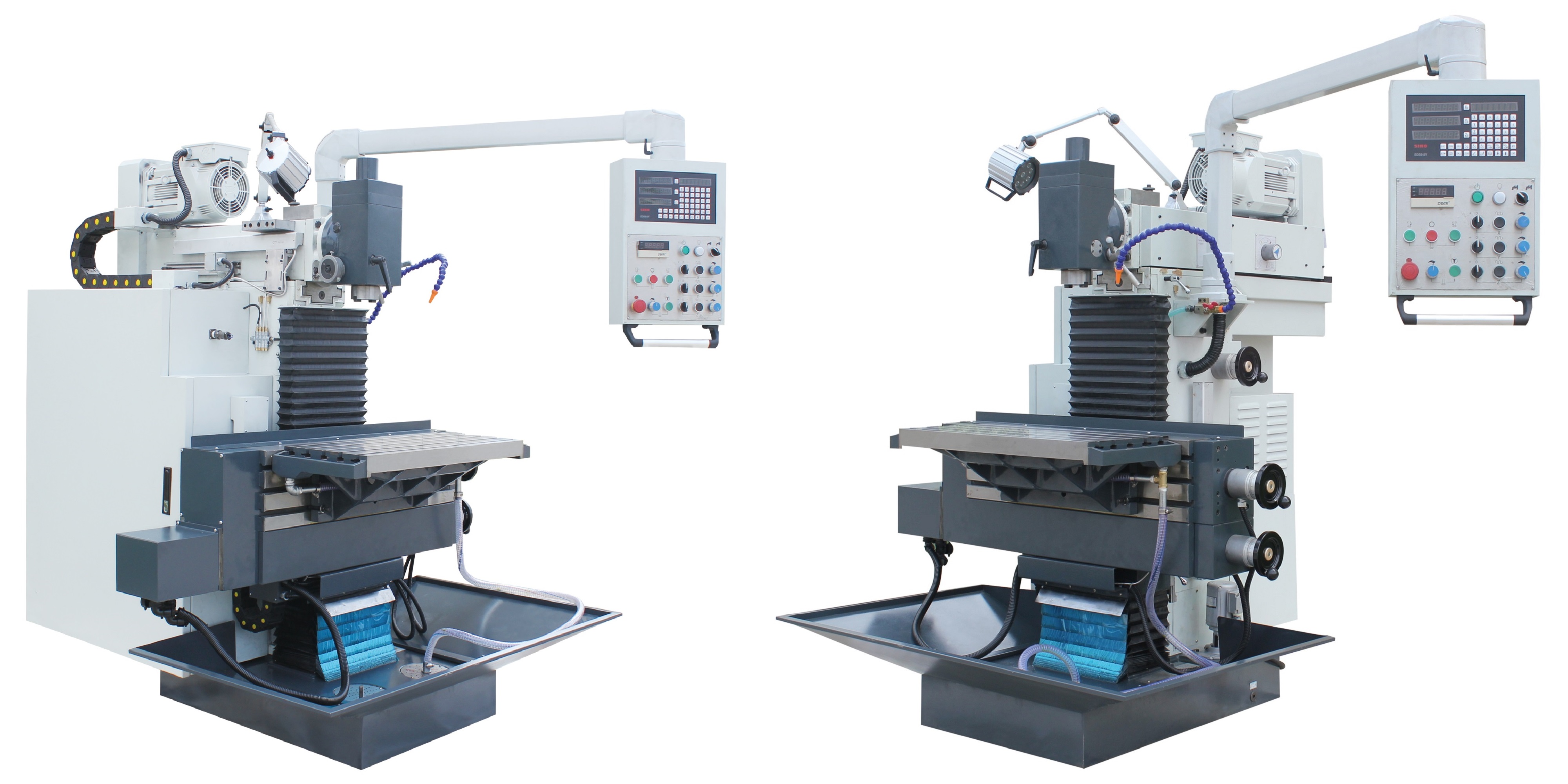

Δ Spindle:

√ step-less spindle speed, in high & low speed ranges, suitable for high-speed-fine-machining & low-speed-powerful-machining

√ vertical & horizontal spindles combined, for flexible operation

√ 60mm spindle stroke, milling and drilling functions are available

Δ Working feed:

√ X/Y/Z-axis ball screws, good precision

√ X/Y/Z-axis driven by 3 independent servo motors, can realize X/Y/Z-axis synchronous feeding

√ servo motors for spindle and feeding, machine with low noise, good precision, easy to maintenance

√ X/Y/Z-axis with electronic handwheels, for easy and precise manual-feeding

√ vertical & horizontal combined work-tables, for flexible clamping of workpiece

√ fitted with automatic centralized lubrication system, for automatic timing lubrication

√ X/Y/Z-axis ball screws, good precision

√ X/Y/Z-axis driven by 3 independent servo motors, can realize X/Y/Z-axis synchronous feeding

√ servo motors for spindle and feeding, machine with low noise, good precision, easy to maintenance

√ X/Y/Z-axis with electronic handwheels, for easy and precise manual-feeding

√ vertical & horizontal combined work-tables, for flexible clamping of workpiece

√ fitted with automatic centralized lubrication system, for automatic timing lubrication

Specificaitons of This Series

|

ITEM

|

UNIT

|

XL8132

|

XL8140

|

XL8145

|

|

horizontal table size

|

mm

|

750*320

|

800*400

|

850*450

|

|

T-slots (N/W/D)

|

|

5/14/63

|

6/14/63

|

7/14/63

|

|

vertical table size

|

mm

|

890*225

|

1020*225

|

1190*250

|

|

T-slots (N/W/D)

|

|

3/14/63

|

||

|

max load

|

kg

|

160

|

200

|

300

|

|

X/Y/Z axes travel

|

mm

|

405/305/400

|

500/400/400

|

600/450/450

|

|

spindle taper (H&V)

|

|

NT40

|

||

|

spindle speed (variable)

|

rpm

|

40-2000

|

||

|

stroke of vertical spindle

|

mm

|

60

|

||

|

feed speed (X/Y/Z)

|

mm/min

|

10-1000

|

||

|

rapid feed speed (X/Y/Z)

|

mm/min

|

1200

|

||

|

main motor power

|

kw

|

3.7

|

5.5

|

|

|

feed motor torque (X/Y/Z)

|

Nm

|

7.7/7.7/10

|

10/10/15

|

|

|

overall size

|

mm

|

1500*1700*1800

|

1500*1700*1800

|

1600*1800*2000

|

|

N.W.

|

kg

|

1450

|

1550

|

1750

|

|

packing size (L*W*H)

|

mm

|

1750*2000*2200

|

1750*2000*2200

|

1900*2000*2200

|

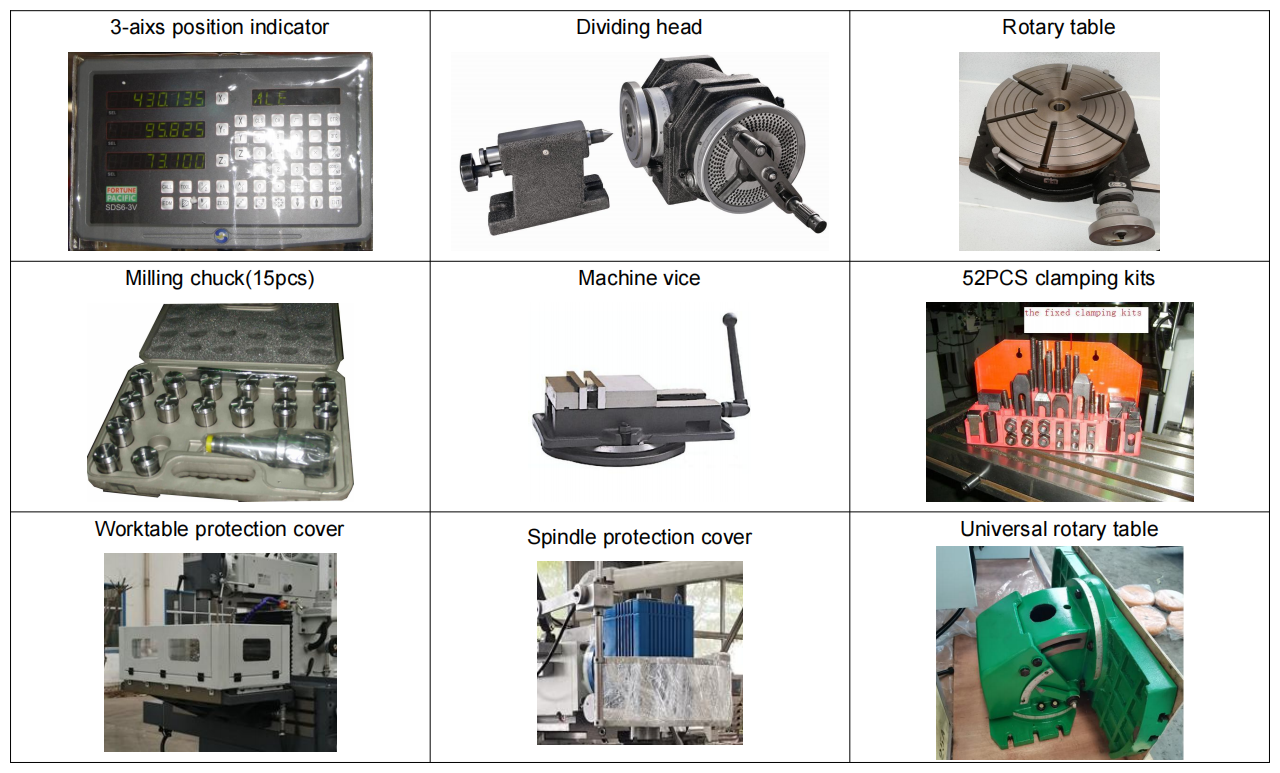

Accessories

|

standard

|

draw bar

|

|

horizontal milling arbor Ø16, Ø22, Ø27, Ø32

|

|

|

reducing sleeve MT1, MT2, MT3

|

|

|

milling check set

|

|

|

horizontal milling support bracket

|

|

|

tools & tool box

|

|

optional |

3-axis DRO

|

|

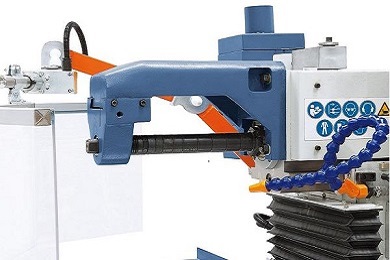

spindle protection guard

|

|

|

work-table protection guard

|

|

|

LED work lamp

|

|

|

specialized universal rotary table (3-axis rotary)

|